mpms_squid_magnetometer

Magnetic Properties Measurement System (MPMS) (수정중)

- Quantum Design MPMS-XL7 model with EverCool system.

MPMS trobleshooting

- MPMS 관련 문제, 해결책, 원인에 대해 기록하자.

- Dewar pressure overshooting and/or undershooting

- MPMS Pump 소음과 더불어 Fan의 고장 (2023.06.16)

History of He regeneration by Evercool system

- He regeneration 이력을 기록하자.

- 2022.06.06, target He level: 63%

*** Important things for MPPS prior to do characterizations

- There are two fundamentally different control mechanisms used in the system. The normal mechanism is used for all temperatures above about 4.4 Kelvin, while below this temperature, control is achieved by controlling the pressure on a small reservoir of liquid helium. The MPMS control system automatically selects the correct mechanism for the specified temperature.

- Note: The crossover temperature, which can be set from the MPMS control system, depends on the boiling point of helium at ambient atmospheric pressure. Hence, its value will vary with the altitude of the user's site. The correct value for the site is normally set by the Quantum Design service representative when the system is installed and may vary from the sea level value of 4.4 Kelvin.

- The helium consumption in the system is approximately 4.5 to 5 liters/day when running the system below about 200 K, increasing to about 6 to 7 liters/day when running at room temperature. While the MPMS dewar has a 56-liter capacity, the superconducting magnet in the system requires the liquid helium level to be at least 35 to 40 percent to operate. Hence, to operate at the highest fields, the liquid helium should be replenished every 5 to 6 days.

- Verify that a helium-gas supply cylinder is attached to the EverCool manifold supply port with a stainless steel hose and that the cylinder pressure is regulated from 5-30 psi (35-210 kPa).

- Check the Helium Level in the chamber at least over 57%.

Maintenance checkpoints

- SUPPLY PRESSURE INDICATION

- Monitor the compressor's supply He gas pressure. In the normal operation with adequate heat loads, the supply helium gas pressure indicates between 2.1 and 2.3 MPa (21.4 and 23.5 kgf/cm2G, 304 and 333 psig). The operating pressure varies according to the heat load of cold head and temperature around the equipment.

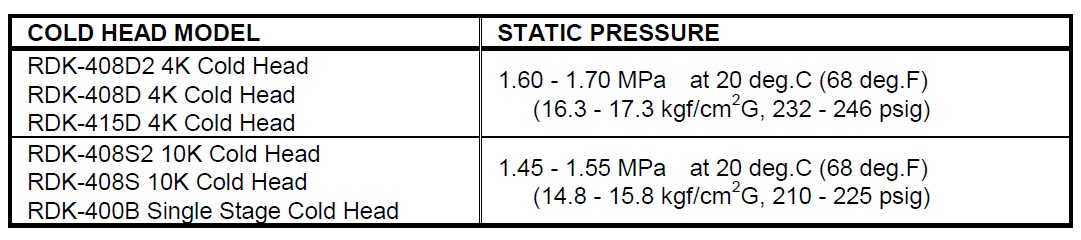

- HELIUM GAS CHARGING

- “IMPORTANT” The filling pressure of the cryocooler varies in accordance with the compressor and coldhead temperature. Make sure the cryocooler is powered off and compressor and coldhead temperatures are almost same as room temperature before adjusting the helium gas pressure.

- Charge helium gas, if the pressure indication of the Compressor Unit is lower than specified value. After stopping the cryocooler, the pressure indication on the Indoor Unit pressure gauge shows lower than actual filling pressure, because of the low temperature of the coldhead. The coldhead temperature and compressor unit temperature needs to be equal to ambient temperature to check the actual filling pressure.

- The filling pressure indication depends on the temperature of cryocooler components, such as Coldhead, Outdoor Unit, Indoor Unit and Flex Lines. In case the room temperature is relatively low, the filling pressure indicates lower. In case the room temperature is relatively high, the filling pressure indicates higher. Refer to the ambient temperature to adjust the filling pressure precisely.

외부 링크

SQUID https://wiki.aalto.fi/pages/viewpage.action?pageId=165132451

mpms_squid_magnetometer.txt · 마지막으로 수정됨: 2023/06/16 16:10 저자 yjchoi